Sideros Engineering SyncroLift

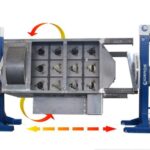

Sideros Engineering Head & Tailstock Positioners are used to weld and assembly long and large weldments in many different application fields. Besides the benefits of ergonomics and safety during welding and assembly applications, the revolutionary feature of Syncrolift is the compactness and the portability of both columns, thanks to their dedicated hydraulic jacks. The result is an extreme flexibility in the factory.

Syncrolift features two main axis: Electrical elevation/descent, and Electrical 360° left/right rotation.

Syncrolift is configured with a fixed to the ground motorized headstock and an idler tailstock to adjust the workpiece lenght.

Advantages:

- Improved Safety

- Proper Ergonomics

- Improved weld quality

- Cost savings and profit increase

- Welding/Assembly procedures repeatability

Machine Features:

- Master and idler column with rotating mounting plates

- Pallet jacks for column lifting and relocating

- Servo-motor, ball screw and encoder control for Up & Down motion

- Servo-motor, gear reducer and encoder control for Rotation

- LCD display for positioning set up, safety thresholds setting and diagnostic

- Automatic load leveling

- Redundant safeties – servo motor brake, ball screw thread geometry and mechanical Stopper

- Low maintenance

- 240/480/600 Volt – 3 phase – 60 Hz

WAM Australia – SYNCROLIFT 2021 Specifications